Corrugated Box Manufacturing in West Bengal: A Complete Guide

Corrugated boxes are the backbone of the packaging industry—used across retail, e-commerce, agriculture, and industrial supply chains. If you’re looking for a reliable corrugated box manufacturer in West Bengal, you’re in the right place. This guide explores everything you need to know, whether you’re a business sourcing bulk boxes or a startup planning sustainable packaging.

West Bengal, particularly cities like Kolkata, Howrah, and Siliguri, is home to some of India’s most established and innovative corrugated box manufacturers. This guide is your all-in-one resource for understanding the market, finding suppliers, comparing products, and making informed decisions.

Table of Contents

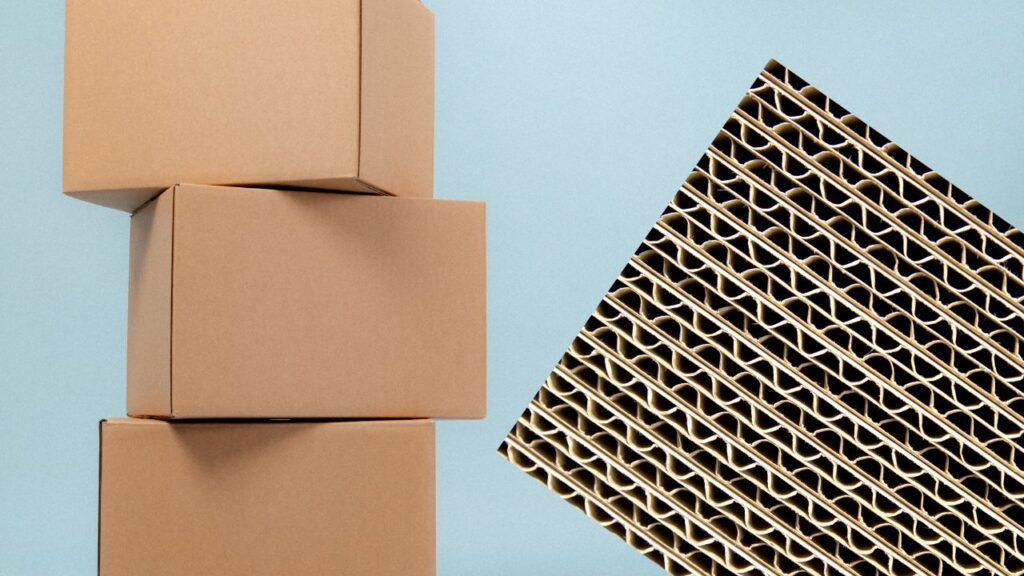

What Are Corrugated Boxes?

Corrugated boxes are cardboard-based packaging solutions known for their durability and recyclability. Unlike regular cardboard, they consist of three layers:

- Outer liner

- Corrugated (fluted) medium

- Inner liner

These layers provide strength, cushioning, and protection, making them ideal for shipping and storage.

Key Benefits:

- Lightweight yet strong

- Cost-effective

- Customizable sizes

- Biodegradable and recyclable

Why Choose a Corrugated Box Manufacturer in West Bengal?

West Bengal offers a strong manufacturing ecosystem due to its strategic location, skilled labor, and access to raw materials.

Advantages of Sourcing Locally:

- Proximity to major eastern ports (Kolkata)

- Lower logistics costs

- Access to jute and paper mills

- Quick turnaround times

Key Manufacturing Hubs in West Bengal:

Key Manufacturing Hubs in West Bengal:

- Kolkata – Industrial packaging and bulk manufacturing

- Howrah – Machinery and corrugated sheet production

- Siliguri – Northern distribution and agro-packaging

Why Choose a Corrugated Box Manufacturer in West Bengal?

Corrugated box manufacturers in West Bengal offer a wide variety of products. Here’s a breakdown:

By Wall Type:

- Single Wall – Ideal for lightweight products

- Double Wall – Offers extra strength for heavier goods

- Triple Wall – Heavy-duty use in industrial sectors

By Style:

- Regular Slotted Containers (RSC)

- Die-cut Boxes

- Telescopic Boxes

- Corrugated Trays

- Wrap-around Boxes

By Flute Grade:

| Flute Type | Thickness | Best For |

|---|---|---|

| A-Flute | 4.8 mm | Cushioning and protection |

| B-Flute | 3.2 mm | Retail packaging and displays |

| C-Flute | 4.0 mm | General-purpose packaging |

| E-Flute | 1.6 mm | Lightweight boxes, fine printing |

| F-Flute | 0.8 mm | High-end, luxury packaging |

How to Choose the Right Corrugated Box Manufacturer

Selecting a reliable manufacturer requires due diligence. Consider these factors:

1. Product Range

Ensure the manufacturer offers the specific types and sizes you need.

2. Quality Standards

Look for ISO, FSSAI, or other relevant certifications.

3. Customization Options

Can they offer logo printing, die cuts, and unique box dimensions?

4. Pricing Transparency

Request itemized quotes to avoid hidden charges.

5. Delivery & Logistics

Check their ability to meet delivery timelines and support bulk orders.

Applications of Corrugated Packaging

Corrugated boxes are versatile and span various industries:

| Industry | Application Examples |

|---|---|

| E-commerce | Shipping boxes, returnable packaging |

| FMCG | Retail-ready boxes, promotional packs |

| Electronics | Anti-static packaging, inserts |

| Agriculture | Fruit and vegetable trays, ventilated boxes |

| Pharmaceuticals | Tamper-proof medical cartons |

| Textiles | Garment shipping, hanger boxes |

Cost Factors & Pricing Table

Pricing varies based on material, size, volume, and printing. Here’s a sample pricing table:

| Box Type | Size (inches) | Quantity | Price/Box (INR) |

|---|---|---|---|

| Single Wall RSC | 12 x 12 x 12 | 1000 | ₹9.00 |

| Double Wall RSC | 18 x 12 x 12 | 500 | ₹16.00 |

| Printed Die-cut Box | 10 x 10 x 5 | 2000 | ₹14.00 |

| Corrugated Tray | Custom | 1000 | ₹11.00 |

Note: Prices vary by manufacturer, material quality, and location.

Sustainability in Corrugated Packaging

West Bengal’s manufacturers are increasingly adopting eco-friendly practices:

Sustainability in Corrugated Packaging

Trends in Green Packaging:

- Recycled and FSC-certified paper

- Water-based inks

- Energy-efficient production

Benefits:

- Lower carbon footprint

- Meets global compliance norms

- Enhances brand image

Industry Standards and Certifications

Look for these industry benchmarks to ensure quality:

- ISO 9001 – Quality Management

- FSC Certification – Sustainable forest sourcing

- BRC Packaging – Hygiene and safety for food packaging

- FSSAI – For food-contact packaging

Frequently Asked Questions (FAQs)

1. What is the minimum order quantity (MOQ)?

Most manufacturers have MOQs ranging from 500 to 1000 units depending on customization.

2. Can I get custom printing on small batches?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

3. Do manufacturers ship outside West Bengal?

Absolutely. Most offer shipping across India and some even export.

4. How long does production typically take?

Lead time varies between 7 to 21 days based on order size and complexity.

5. What is the difference between corrugated and cardboard?

Corrugated boxes have multiple layers with fluting, offering better strength than standard cardboard.